Track short circuit preventive prediction and cause analysis

The implementation of Track Short Circuit Preventive Prediction and Cause Analysis system in the railway industry offers significant benefits in terms of safety, operational efficiency, and maintenance planning. One key advantage is the ability to detect train position accurately and in real-time. By utilizing advanced technologies such as train position detection systems, the system provides precise information on the location of trains along the tracks. This enables efficient trail tracking and signaling, allowing operators to anticipate potential short circuit situations and take preventive measures. By proactively addressing the risk of short circuits, the system significantly reduces the likelihood of electrical failures, signal disruptions, and related accidents, ultimately enhancing overall railway safety.

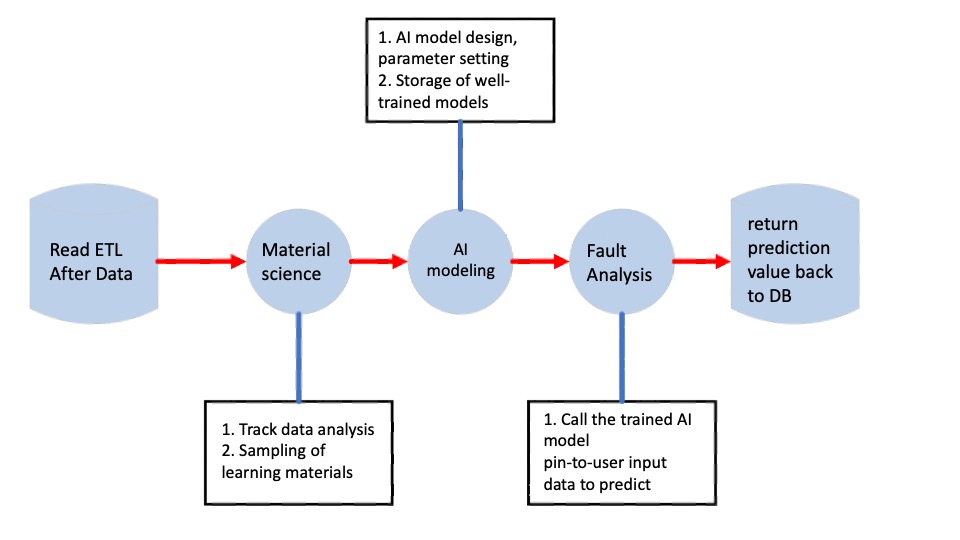

The Track Short Circuit Preventive Prediction and Cause Analysis system also plays a vital role in maintenance planning and resource optimization. By analyzing data and conducting cause analysis, the system can identify potential causes of short circuits, such as faulty electrical equipment or damaged insulation. This information enables operators to prioritize maintenance activities and allocate resources effectively. With a proactive maintenance approach, operators can address potential issues before they lead to major disruptions or costly repairs. Additionally, the system helps in optimizing maintenance schedules, ensuring that inspections, repairs, and replacements are performed at the most opportune times. By minimizing unplanned downtime and maximizing maintenance efficiency, the system reduces operational costs and improves overall railway performance, contributing to increased operational efficiency and customer satisfaction.

The track circuit serves three main functions:

- Train position detection

- Speed code transmission

- Train TWC message exchange.

It operates by dividing the track into blocks, each equipped with a transmitting-end impedance taper and a receiving-end impedance taper. The transmitter continuously sends a voltage signal to the receiver, but when a train enters a block, the signal is blocked, causing the receiver's relay to demagnetize and generate an occupation signal. This allows the current train's position to be determined by monitoring the occupied signal. However, the stability of train operation is crucial for the track circuit's normal functioning. If the receiving end circuit malfunctions, false occupation signals may be generated, leading to nearby trains mistakenly assuming the presence of a train ahead and initiating braking actions. To mitigate such failures, maintenance personnel conduct inspections every six months. Nevertheless, the extended inspection interval may not facilitate pre-failure repairs.